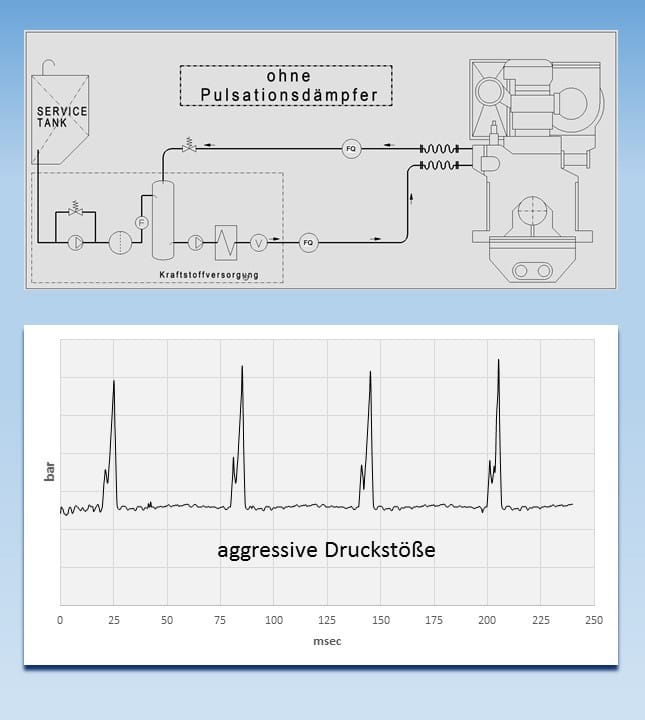

Fuel supply systems for marine diesel engines are exposed to very fast pressure peaks by the injection pumps. The peak values are often multople of the designed system pressure. Pressure limits of installed components are exceeded.

The consequences are damages to sensors, filters and fittings. Even pipelines have already burst under these extreme loads and fuel has leaked uncontrolled. Today, fuel consumption is often measured with mass flow devices (Coriolis principle), each installed in the supply and return to the diesel engines. Occurring measurement errors are not uncommon here.

MARINE TECHNIK Manfred Schmidt GmbH designed the pulsationdamper type PAPS in the 1990th and it was patent registered in 2001.

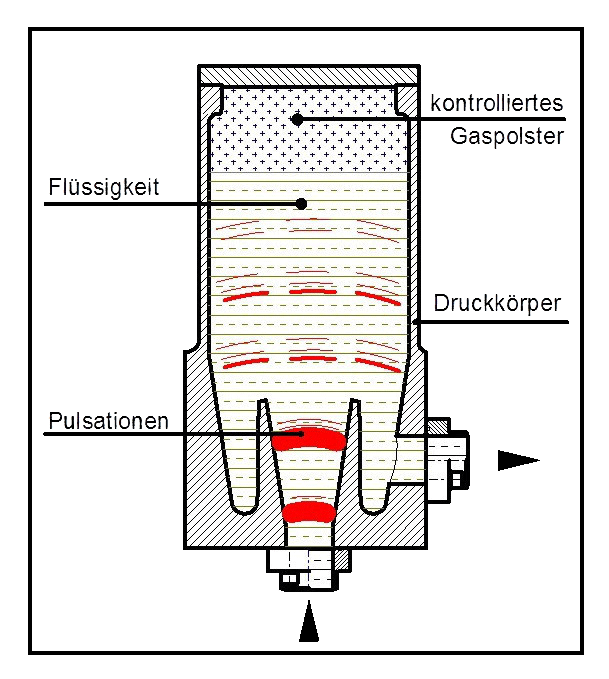

Pressure impulses are dierected from below into a pressure chamber and will be absorbed by an encapsulated, controlled air cushion.

The PAPS pulsation damper was subject to comprehensive test series at the Institute for Ship Operation Research (ISF) in Flensburg. These tests impressively proved the effectiveness and confirmed the gas cushion as the most effective damping.

The new series „PAPS-PE 18“ combines proven damping technology with state-of-the-art measuring and control technology. The damping principle has remained unchanged. As with the predecessors, the pressure pulses are directed into the pressure chamber from below without reflection and are almost completely absorbed by the encapsulated air cushion.

Completely revised was the level detection and level control, which can be continuously changed and adapted. The level is continuously recorded by an electronic sensor and processed by the PLC control. Two solenoid valves regulate the gas cushion, depending on the state of air is tracked or the gas cushion is reduced, thus the level is changing.

Special emphasis was placed on operational safety. The entry of air into the fuel system to the engine must be avoided in any operating condition. In the event of a pressure drop in the fuel system, the air cushion expands and triggers the safety degassing, which acts completely independently from the PLC control.

With the flexible control and the infinitely variable air cushion, the pulsation damper is suitable for diesel engines of all makers. Pulsation dampers should be installed in both, the supply line and the return line to the engine, to ensure optimum protection.

The robust design with stainless steel components ensure virtually maintenance-free operation. The well-known reliability in MGO operation is achieved with the new series also in operation with HFO and its partly indefinable substances.

The compact control unit can be combined with pressure chambers of different materials and designs. This allows the use of the pulsation damper in almost all fluid systems with media of various kinds.

The new „PAPS-PE 18“ combines state-of-the-art measuring technology and reliable components into a unit that is unrivalled in its effectiveness.