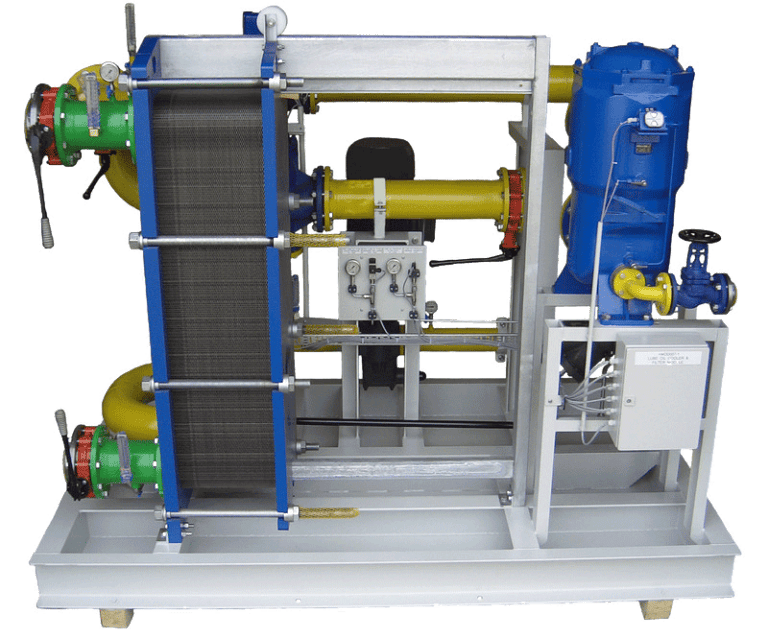

An important task is the proper treatment of lubricating oil to minimize the wear of rotating components on diesel engines. Lubricating oil circulates continuously through the diesel engine, where, for example crankshafts and connecting rod bearings are lubricated. Impurities from abrasion are filtered out in the module and the oil is cooled down afterwards.

Main Components:

The purpose:

The purpose of the lube oil replenishing oil module is to provide either fresh lube oil replenishing of diesel engine for „topping-up“ or for maintenance lube oil re-filling after maintenance / major overhaul of diesel engine. The quantity of fresh lube oil delivered will be measured by Flow Quantity Counter. This counter will only measure fresh lube oil supplied to the diesel engine.

The 3-way manual selection valve is used to either allow the cleaned lube oil from separator module to be re-circulated back into the engine lube oil frame tank for normal operation or to use the lube oil separator feed pump to drain the engine lube oil frame tank by means of switching the 3-way valve into position to maintenance lube oil buffer tank.

Write us an email to office@marine-technik.com

We look forward to your call.

Alternatively, please use our contact form.